OUR PROJECTS

Hydraulic Pump Units relocation

This project involved relocating 6 HPU (hydraulic Power Units) from inside an aviation painting hanger to outside. The HPUs are used to power platforms used to easily access and reach various parts of the aircraft in order to prepare and paint the exterior.

These HPUs where located close to the hanger’s roof at a height of approximately 15mtrs above the ground and in order to access them a cherry picker was needed, once there was an aircraft in the hanger, access was nearly impossible, furthermore the HPUs where exposed to constant high temperatures and dust which are not ideal for hydraulic systems. Our company was responsible for the repairs and maintenance of the entire plant and it’s equipment.

In order to perform the maintenance and repairs on these HPUs was not cost effective, therefore we’ve suggested to relocate the HPUs on the ground outside the hanger, ewhere it would be easier to access and maintain, away from the high temperature and dust. For a small strategic investment our customers minimized the cost for maintaining and repairing the units while reducing the breakdowns.

Since the units where located at height we had to co-ordinate the use of cranes and cherry pickers to dis assemble and lower the units safely to the ground where they have been transported to their new position outside the hanger.

New hydraulic lines and wires had to be run the newly added cable trays which we fabricated and installed, made penetrations through the hunger walls for the lines and wires.

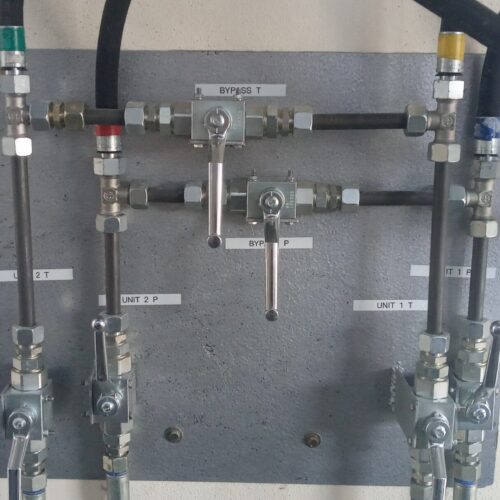

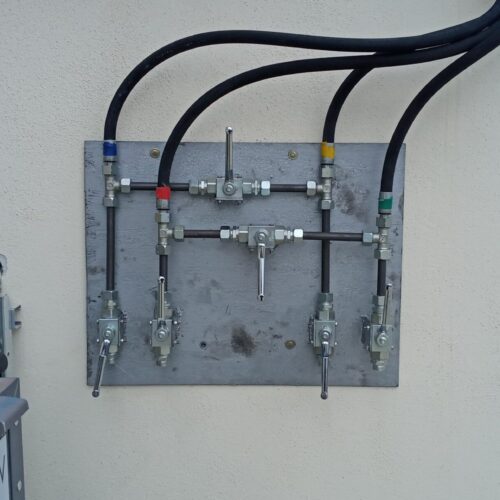

Furthermore we’ve designed and fabricated a cross over system where in case of failure in one of the pumps the pump next to it can operate the platform of the failed HPU to reduce down time and late fees on our clients.

It was an interesting and exciting project to work on despite the challenges it came with which resulted in a big satisfaction and appreciation by our customers.

Compressors installations

During this project our company was entrusted to install 3 brand new screw type compressors, and an air dryer in a concrete casting plant. The compressors where an addition to the plant’s existing ones which where located in a designated room, while the ones we’ve installed where positioned around the plant, with one of them on a platform above ground at 3.5m height.

As part of the project we had to design and install new pipework, various pressure regulators, Pressure relief Valves (PRV), water separators, outlets, isolation valves, filters, automatic draining valves, pressure gauges and laying of armoured electrical cables.

Co-ordination with the plant manager was key in this project in order not to slow down or halt operations, as some of the new compressors had to be tapped in the existing air supply system which was still being used during production.

The plant owners expressed the desire to keep and re use some of their own systems and therefore thorough planning and designing was undertaken to meet the client’s needs and requests.

The clients where highly impressed and satisfied with the equipment and installation, as we delivered what they wanted and needed while keeping costs to the minimum possible.

Marine Engine Servicing

We had the opportunity to showcase my expertise in servicing and replacing parts for a marine engine. This challenging project required a combination of skillful engineering and the use of specialized tools. Here’s an account of the key topics involved in completing this task and leaving the engine fitted in and ready for several more hours of service:

Assessment and Disassembly: I began by thoroughly assessing the marine engine, drawing upon my knowledge of its intricacies and technical specifications. Careful disassembly of the engine components followed, ensuring the use of appropriate tools to maintain precision and prevent any damage.

Parts Inspection and Replacement: Each part underwent meticulous inspection to identify worn-out or faulty components. With my expertise, I selected and replaced parts such as piston rings, valves, gaskets, and bearings, ensuring compatibility with the engine’s specifications and optimal performance.

Lubrication: Proper lubrication is vital for the engine’s longevity and efficiency. I skillfully applied high-quality lubricants to critical areas, including the crankshaft and camshaft, minimizing frictional losses and enabling smooth operation.

Reassembly: With great precision and attention to detail, I reassembled the engine, adhering strictly to torque specifications. This ensured secure fastening of all components, eliminating potential risks and maintaining optimal performance.

Testing and Monitoring: The final step involved a rigorous testing phase. I started the engine and carefully monitored its performance, checking for any abnormalities. Thorough tests were conducted to assess fuel efficiency, cooling system functionality, and overall performance.

My expertise and the use of specialized tools enabled me to successfully service and replace parts for the marine engine. Through meticulous assessment, disassembly, inspection, replacement, lubrication, reassembly, testing, and monitoring, I ensured the engine’s optimal performance and reliability. The engine now stands fitted in and ready for several more hours of reliable service on the open water.