Engineering Works

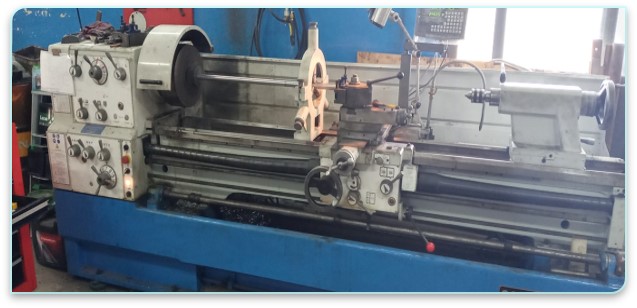

In the dynamic world of engineering, the ability to meet diverse and demanding requirements is crucial for success. As an engineer, I am delighted to present our company, a leading provider of custom engineering works. With our cutting-edge Heavy-Duty Lathe, boasting impressive specifications such as a 2000mm (2m) between centres, 560mm diameter swing, Digital Read Out (DRO) for precise work, and a Taper Turning attachment, we excel in delivering exceptional craftsmanship while meeting today’s industry demands.

Unveiling the Power of our Heavy-Duty Lathe

Our company takes pride in the capabilities of our Heavy-Duty Lathe, a key asset that enables us to undertake a wide range of engineering projects. This state-of-the-art machinery is designed to handle robust components and intricate workpieces with precision, efficiency, and reliability.

2000mm (2m) Between Centres: Mastering Lengthy Workpieces

One standout feature of our Heavy-Duty Lathe is its remarkable 2000mm (2m) between centres capacity. This spacious working area allows us to handle lengthy workpieces, catering to the needs of various industries such as oil and gas, manufacturing, and heavy machinery. Whether it’s fabricating long shafts, cylinders, or rods, our lathe provides the necessary space for seamless machining and precision turning.

560mm Diameter Swing: Embracing Versatility

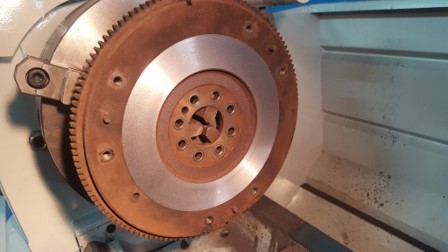

Equipped with a 560mm diameter swing, our Heavy-Duty Lathe offers versatility in accommodating workpieces of varying sizes and complexities. This broad swing capacity empowers us to undertake a wide range of engineering projects, from small-scale precision components to large industrial parts. By providing ample clearance, we can execute turning operations accurately and efficiently, ensuring high-quality end products.

Digital Read Out (DRO): Achieving Unparalleled Precision

Precision is the cornerstone of any engineering work, and our Heavy-Duty Lathe is equipped with a Digital Read Out (DRO) system to deliver unrivaled accuracy. The DRO technology provides real-time measurements of tool positions, enabling our skilled operators to achieve precise dimensions, tight tolerances, and smooth surface finishes. With this advanced feature, we can execute complex turning operations with confidence, meeting the most demanding specifications.

Taper Turning Attachment: Expanding Capabilities

To further enhance our capabilities, our Heavy-Duty Lathe is equipped with a Taper Turning attachment. Taper turning involves machining workpieces with non-uniform diameters, gradually transitioning from a larger diameter to a smaller one or vice versa. This attachment enables us to tackle intricate projects that require conical shapes, such as tapered shafts, threads, and tooling. By incorporating taper turning into our repertoire, we expand the scope of custom engineering works we can undertake, catering to a wider range of client needs.

Meeting Today’s Engineering Demands

In today’s fast-paced and competitive engineering landscape, our company remains at the forefront of innovation and craftsmanship. Through the utilization of our Heavy-Duty Lathe, we offer customized engineering solutions that meet the highest industry standards. Whether it’s turning, threading, tapering, or facing, our skilled technicians leverage the full potential of our lathe to deliver precision-engineered components that meet the exact requirements of our clients.

Conclusion

As engineers, we understand the importance of advanced machinery and expertise in delivering exceptional results. With our Heavy-Duty Lathe, boasting a 2000mm (2m) between centres, 560mm diameter swing, Digital Read Out (DRO), and Taper Turning attachment, we are well-equipped to handle a diverse range of custom engineering works. Our commitment to precision, efficiency, and meeting today’s demands